Girder Slab System for Floor & Roof

Durable, Dependable, Distinctive.

ABOUT - Girder Slab System for Floor & Roof

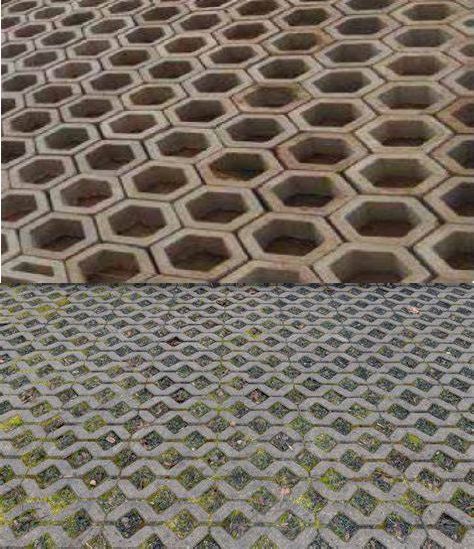

The Girder Slab System is an innovative pre-cast concrete solution designed for floor and roof applications. Engineered to provide exceptional structural integrity, this system integrates seamlessly with other building components, offering a reliable and efficient construction method. The Girder Slab System is widely used in various construction projects, including residential, commercial, and industrial buildings, due to its strength, durability, and design flexibility. This system ensures a stable and robust framework, making it an ideal choice for modern construction needs.

For enhancing the structural integrity of floors and roofs, the Girder Slab System is frequently the preferred option. UMER Concrete offers a comprehensive range of Girder Slab Systems designed to meet various construction needs. These slabs are produced using automated plants with precise batching processes and are cast in imported molds. The production facilities utilize hydraulic presses and strong eccentric vibrating forces to shape the slabs, incorporating advanced techniques to ensure superior strength and durability.

Advantages

Durability: The Girder Slab System is known for its exceptional strength and durability, capable of supporting substantial loads and providing long-lasting performance, robust design to resist structural failures, ensuring longevity with minimal maintenance.

Structural Integrity: This system enhances the overall structural integrity of floors and roofs, distributing loads evenly and reducing stress on individual components. It offers superior stability and reliability for a wide range of construction projects.

Versatility and Flexibility: The Girder Slab System can be customized to meet specific project requirements, offering flexibility in design and application. It is suitable for various building types, including residential, commercial, and industrial structures.

Efficient Installation: Produced in automated plants with precise batching processes, this Slab System allows for efficient and streamlined installation, reduces construction time and labor costs, making it an ideal choice for large-scale projects.

Cost-Effective: Despite the initial investment, the Girder Slab System proves cost-effective in the long run due to its durability, low maintenance requirements, and efficiency in installation, offering significant savings over time.

Environmental Benefits: The production process of the Girder Slab System is optimized for sustainability, utilizing energy-efficient methods and recyclable materials. This contributes to reduced environmental impact and supports green building practices.

Applications

Commercial Buildings: The Girder Slab System provides robust support for multi-story commercial structures, ensuring long-lasting stability and load-bearing capacity.

Residential Projects: Ideal for homes and apartments, this system offers a strong, reliable framework for floors and roofs, enhancing overall structural integrity.

Industrial Facilities: Suitable for factories and warehouses, the Girder Slab System supports heavy machinery and equipment, ensuring durability and stability.

Parking Structures: Perfect for parking garages, this system provides a stable, crack-resistant surface capable of supporting the weight of vehicles making it an ideal choice.

Institutional Buildings: For schools, hospitals, and government buildings, the Girder Slab System offers reliable support and accommodates large spans and heavy loads.

Infrastructure Projects: Used in bridges and overpasses, the system provides essential support and stability for critical infrastructure.

Renovation and Retrofitting: In renovation and retrofitting projects, pre-cast concrete girders can enhance the structural integrity of existing buildings. They offer a practical solution for upgrading older structures.

Traffic Circles and Roundabouts: Their ability to handle high stress and their ease of maintenance make them ideal for use in traffic circles and roundabouts.

Loading Docks and Heavy Duty Pavements: In industrial settings, interlock pavers are used for loading docks and heavy-duty pavements due to their capacity to bear significant weight and their resistance to wear

picture gallery